MACHINE THEORY AND DYNAMICS LABORATORY

Determination of natural frequencies and modes can be obtained with sensors that provide acceleration and force measurements and the MEScope software that collects information from these sensors. Tests can be conducted on continuously variable transmission systems using the Toroidal Cut test setup. Test setups are also available for various mechanisms (four-bar, crank-connecting rod, cam, etc.). There are experimental setups and tests for electrohydraulic valves, where position-controlled experiments can be conducted.

Laboratory Test Setups:

Closed Force Cam Mechanism Tests

Continuously Variable Transmission Tests with Toroidal Cut Test Setup

Determination of Critical Speeds of Shafts Test Setup

Motion Determination of Four-Bar Mechanism

Motion Determination of Crank-Connecting Rod Mechanism

Experimental studies for determination of natural frequencies and modes

Acceleration and Force Measurements

Electrohydraulic Position-Controlled Valve Test Setup

Pneumatic and Hydraulic Valve Test Setups

Important Projects Conducted or Ongoing in the Laboratory:

SAN-TEZ Project “Toroidal Cut Test Setup” Uludağ University – Coşkunöz Holding

MACHINE ELEMENTS AND MECHANICS LABORATORY

During the determination of gear efficiency, the input (electric motor) and output (work machine) forces are read from a PLC screen via load cells connected to the system's input and output. Gear efficiency can be found under different speeds and loading conditions.

Gear impact resistance measurements are obtained by converting the dynamic force into an electrical signal when the impactor (striker), equipped with a force gauge, drops from a certain height and hits a tooth on the gear wheel on the ground. This electrical signal is amplified in an amplifier and transferred to a computer via a data collector, and graphs are generated using a computer program.

The specimen connected to the fatigue test setup is subjected to repeated loads under input parameters such as frequency, offset, and amplitude provided by the computer system, and its fracture and crack behavior is examined.

In the setup, the pressure resulting from the strain on the strain gauge cell connected to the Wheatstone bridge determines the force or pressure applied to the surface where the strain gauge is mounted, based on the resistance change due to the strain.

Laboratory Test Setups:

Gear Efficiency Determination Test Setup

Gear Wheel Impact Resistance Determination Test Setup

Fatigue Test Setup

Strain Gauge Test Setup

Important Projects Conducted or Ongoing in the Laboratory:

BAP Project, "Experimental Investigation of Impact Resistance of Involute Gears," Uludağ University

TÜBİTAK 1002 Project, "Experimental Investigation of Impact Resistance of Standard and Asymmetric Gears," Uludağ University

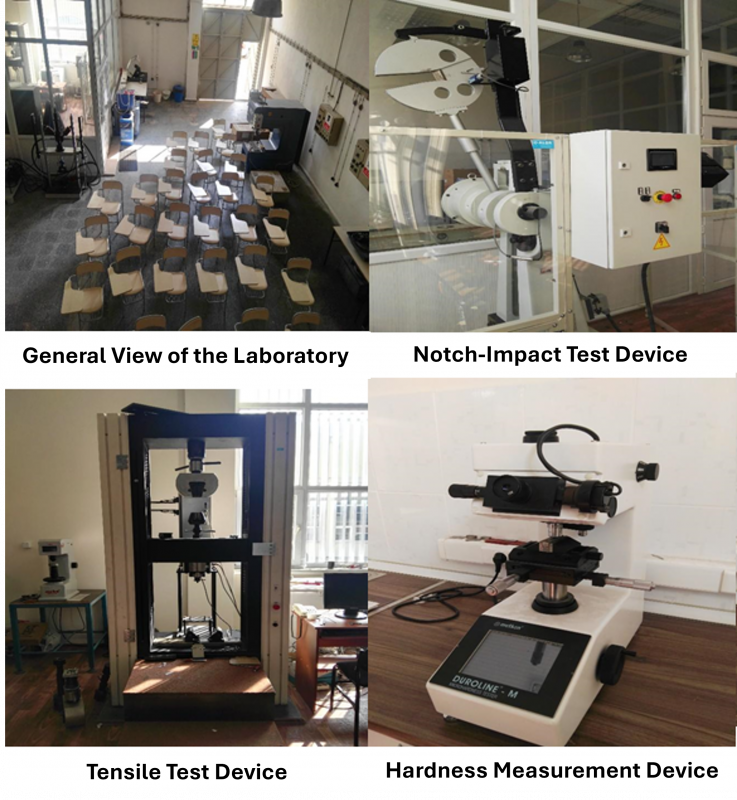

MATERIALS LABORATORY

Mechanical tests are conducted to understand the properties of materials. One of the most important tests is the tensile test, which provides information about the material's mechanical properties. The aim of the tensile test is to determine the elastic and plastic behavior of materials under static loads. The impact test is used to determine the mechanical properties of materials operating under conditions that may cause brittle fracture. The general purpose of the impact test is to determine the energy required for the fracture of metallic materials under dynamic loading and to determine the ductile-to-brittle transition temperature.

Laboratory Test Setups:

Tensile Test Setup

Notch Impact Test Setup

Grinding and Polishing Machine

Metal Cutting Machine

Microscope

Hardness Measurement Device

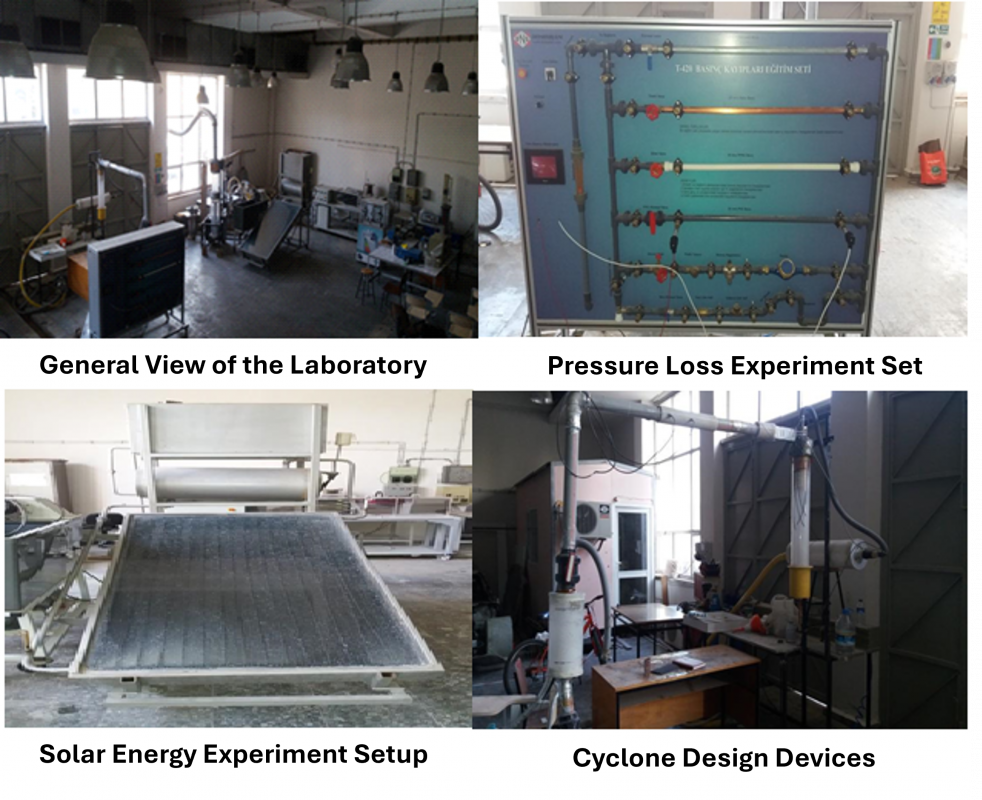

HEAT TECHNOLOGY LABORATORY

The heat technology laboratory has practical experimental devices that explain the basic principles of some theoretical topics taught in heat transfer and thermodynamics courses. Basic engineering measurements such as air, water, and product temperatures, flow rate, weight, heat energy, emissivity, and air velocity are conducted during the experiments.

Laboratory Test Setups:

Full Air Conditioning System

Pressure Losses

Determination of Heat Conduction Coefficients of Solids

Drying Experiment

Solar Energy Experiment

Radiation Experiment

Important Projects Conducted or Ongoing in the Laboratory:

TÜBİTAK Project "Design and Optimization of Performance Characteristics of Next Generation Cyclone Separators" Bursa Uludağ University

BAP Project "Experimental and Numerical Investigation of Simultaneous Heat and Mass Transfer in Industrial Materials" Bursa Uludağ University